Sustainability at Spinnova

Sustainability is the very foundation of Spinnova’s business. The company’s technology was created to solve major sustainability challenges in the global textile industry.

While bringing a sustainable solution to the market, Spinnova is determined to ensure that the Company’s own operations are also as sustainable as possible. Spinnova is committed to protecting the environment and respecting human rights in everything the company does. Spinnova constantly develops its sustainability processes, such as due diligence and responsible sourcing, to understand and address the impacts from its operations on people and the planet.

Spinnova’s sustainability approach

Sustainability is one of Spinnova’s highlighted values, alongside trust, courage, innovation, and teamwork.

The three main themes of Spinnova’s sustainability agenda are passionately innovative, climate champion and naturally circular. The company will only succeed in these main themes by building them on responsible business practices, which form the fundamentals of the agenda.

Key themes

Passionately innovative

Groundbreaking innovation is in the DNA of the company. We test and learn to ensure the biggest possible impact.

Climate champion

Spinnova is a pro-climate company: from raw materials and production to the behaviour we encourage in all our stakeholders. Our technology enables textile fibre production with low carbon emissions and climate benefits.

Naturally circular

Spinnova applies circular principles that go way beyond recycling – both in own operations and value chain. We encourage our partners to join us in the transition to a circular economy.

Fundamentals

Ethics & integrity

Business ethics and compliance

People

Occupational health and safety

Employee wellbeing and development

Local communities

Value chain

Responsible value chain

Biodiversity and land use

Product safety and quality

Read more about our sustainability approach from the Sustainability Reports below. (Part of Annual Report.)

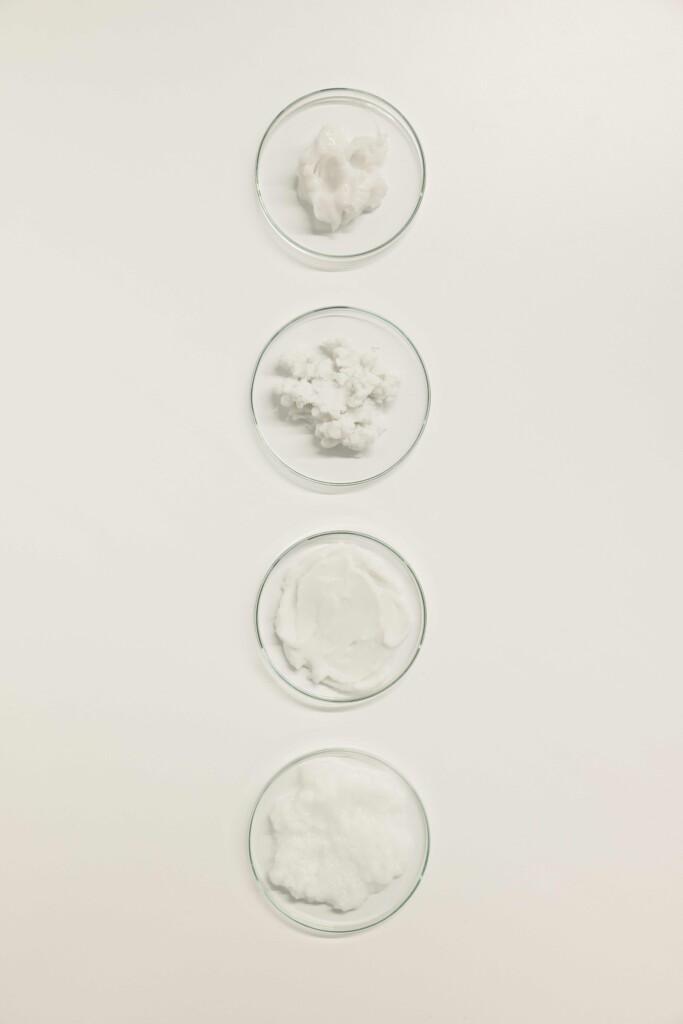

KEY ENVIRONMENTAL BENEFITS OF SPINNOVA® FIBRE

CO2 Emissions

Eucalyptus-based SPINNOVA® fibre’s CO2 emissions are 74% less than conventional cotton’s over the entire lifecycle from farming to fibre process.1

Less water

SPINNOVA® fibre production uses 98% less water than cotton textile production.1

Chemicals

Spinnova’s mechanical production process does not require harmful dissolving chemicals.

In the production of its wood-based fibre and fabric, Spinnova does not use substances that are hazardous to the environment or health. Spinnova does not need environmental permits for its wood-based fibre production facilities.

Responsible value chain

One of the main building blocks of Spinnova’s business model is building solid and inspiring partnerships throughout the value chain.

Responsible raw material sourcing

Spinnova has made a commitment to only use FSC2 certified wood or responsible waste streams. Eucalyptus pulp used by Spinnova’s pilot factory and joint venture Woodspin originates to FSC certified and FSC controlled wood in Brazil. The certification provides third-party assurance of professional, sustainable plantation management. The eucalyptus used to make SPINNOVA® fibre is grown on plantations that were established on degraded land, not replacing natural ecosystems. Both Spinnova’s pilot factory and Woodspin’s factory have received FSC chain of custody certification.

Spinnova has signed the Fibre Procurement Policy for Protecting Forests by Canopy.

Spinnova aims to build a sustainable supply chain. Sustainability requirements for suppliers is set in the Supplier Code of Conduct.

Read more on page 49 in the Annual Review 2023.

Biodiversity and land use

Spinnova aims to ensure that biodiversity is safeguarded and promoted in the company’s value chain. From farming to processing, eucalyptus-based SPINNOVA® fibre needs significantly less land and causes significantly less eutrophication compared to conventional cotton production3. Read more on page 51 in the Annual Review 2023.

Product safety and quality

Product safety is an essential part of Spinnova’s innovation and product development. Spinnova’s production process only utilizes safe, widely used additives. Spinnova provides comprehensive instructions for the safe handling of the very few chemicals used in the process. Read more on page 41 and 52 in the Annual Review 2023.

Business ethics and compliance

Occupational Health and Safety

Read more on page 42 in the Annual Review 2023.

1CO2 e emission comparison is based on a projected product carbon footprint conducted by a third-party expert following the ISO 14067:2018 standard. Ecoinvent database has been used as the source for global average CO2 e emissions of conventional cotton. Water consumption comparison is based on a projected, screening Life Cycle Assessment (LCA) conducted by a third-party expert. Both comparisons include raw material supply, transportation of raw materials, and manufacturing of the product (cradle-to-gate).

2 Source: Spinnova’s FSC® trademark license number is FSC-C179138

3Screening third-party life-cycle impact comparison for the joint venture Woodspin’s factory in Jyväskylä, Finland. Conservative approach excluding the factory’s surplus heat sales which brings further environmental benefits at the system level.