Business

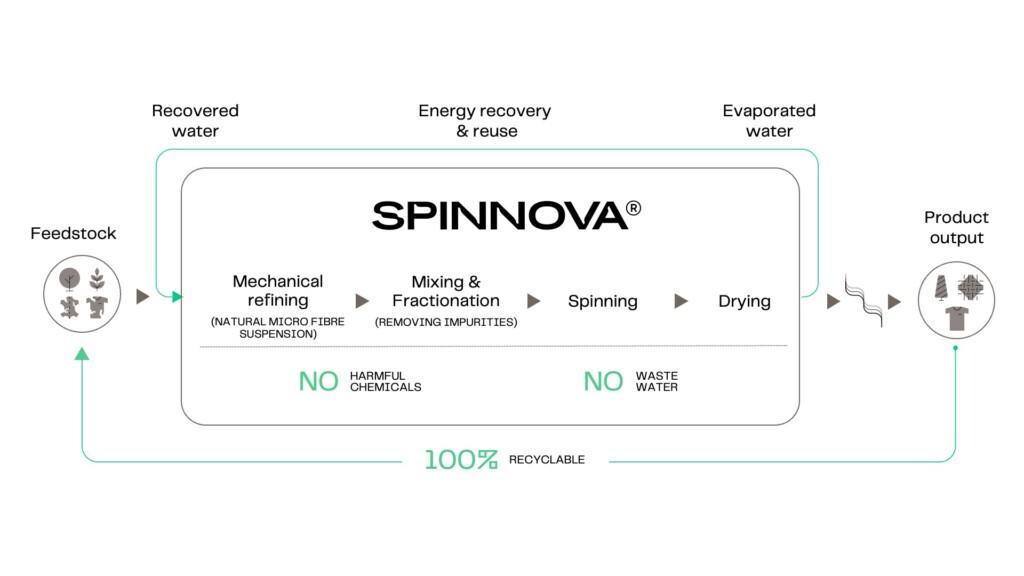

Spinnova offers a scalable solution for the natural fibre gap. Spinnova has developed a production technology for a transformative new textile fibre (“SPINNOVA® fibre”) which is produced with a mechanical production process.

Spinnova’s production technology provides a sustainable alternative for the global textile market. Spinnova’s production technology allows for the production of SPINNOVA® fibre from multiple raw material inputs, including wood and leather waste, and other renewable raw materials such as agricultural, food and beverage industry waste and textile waste.

CO2 emissions of SPINNOVA® fibre are 74% less than for conventional cotton

SPINNOVA® fibre is 100 percent recyclable, quickly biodegradable, contains no microplastics and can be produced without dissolution or the use of harmful chemicals or harmful additives. CO2 emissions from the production of SPINNOVA® fibre are 74 percent less than that of conventional cotton over the lifecycle from farming to fibre processing, and considerably less than that of polyester and viscose.1

Having completed the main phase of research and development, Spinnova is ramping up its global commercialisation phase. Spinnova’s technology platform has been proven effective at the Company’s pilot production facility and in Spinnova’s joint venture Woodspin’s industrial demonstration factory. Both factories are located in Jyväskylä, Finland.

Spinnova’s technology platform and SPINNOVA® brand are protected by strong worldwide intellectual property rights (“IPR”) protection.

1Figures from third-party expert calculation following IS0 14067:2018 standard and emissions databases.

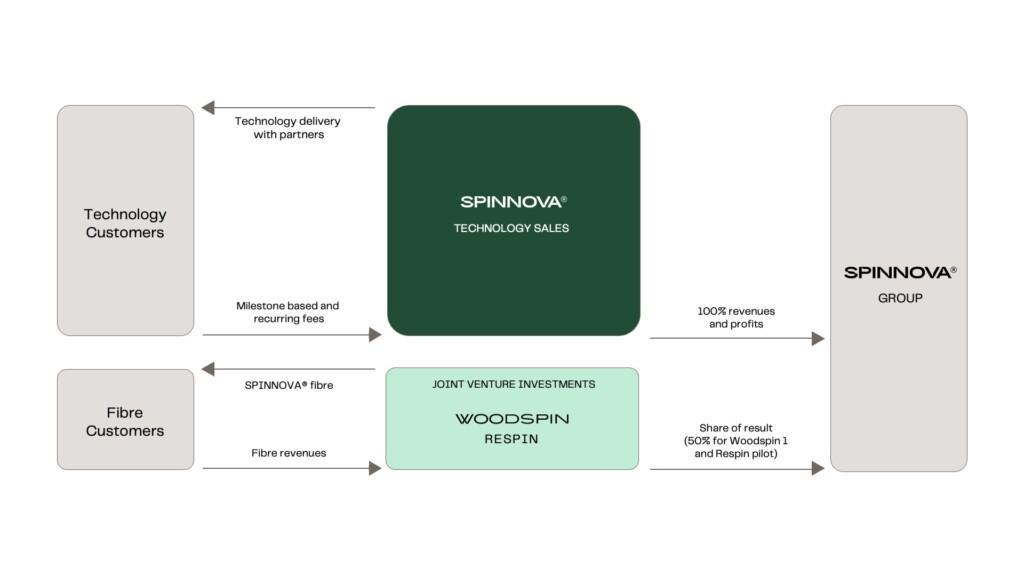

Business model

Spinnova’s business model consists of three parts:

- Spinnova focus on technology sales and delivering the technology together with its partners

- Technology sales are targeted at upstream raw material partners or downstream textile manufacturers

- Spinnova has a 50% ownership in Joint Ventures Woodspin and Respin, which produce SPINNOVA® fibre from wood and leather waste, respectively